Brand: ATORN

Surface: ULTRA M

Length: 54 mm

Art.-no. 16855345

Manufacturer article no. 10617286

EAN 4050293410631

Individual prices for customers after login

Application

HPC end mill for machining rust- and acid-proof steels and titanium and nickel-based alloys, optimal application in trochoidal milling and in edge, corner and groove machining.

Execution

- Solid carbide ultra-fine grain

- ULTRA M high-performance coating

- Centre cutting

- Uneven twist angle: 41°/44°

- Unequal cutting edge pitch

- Optimised cutting edge design

- With clearance

- Cutting edge with edge preparation

Advantage

- Increased material removal rate

- High process reliability owing to robust cutting edges

- Higher feed rates and cutting depths possible

- Reduces vibrations

- Ideal for static and dynamic trochoidal milling

| |

Brand | ATORN |

Main EAN Code | 4050293410631 |

Manufacturer Part Number | 10617286 |

Cutting material | SC |

Surface | ULTRA M |

Type | VA |

Number of cutting edges (Z) | 4 PCS |

Twist angle | 44° |

Tool holding device | HA parallel shank |

Construction length | Normal |

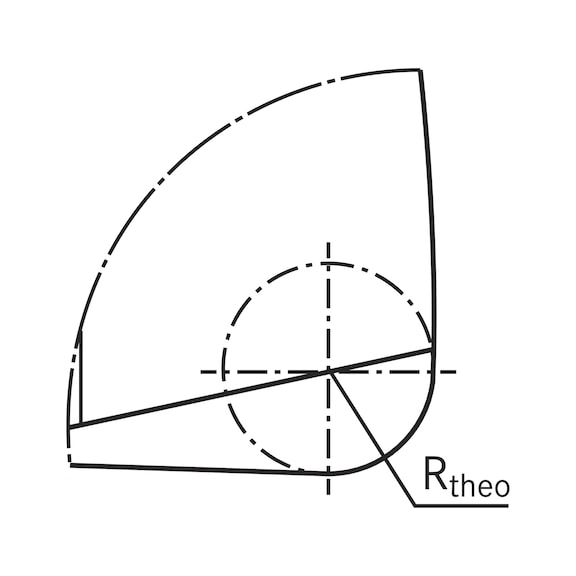

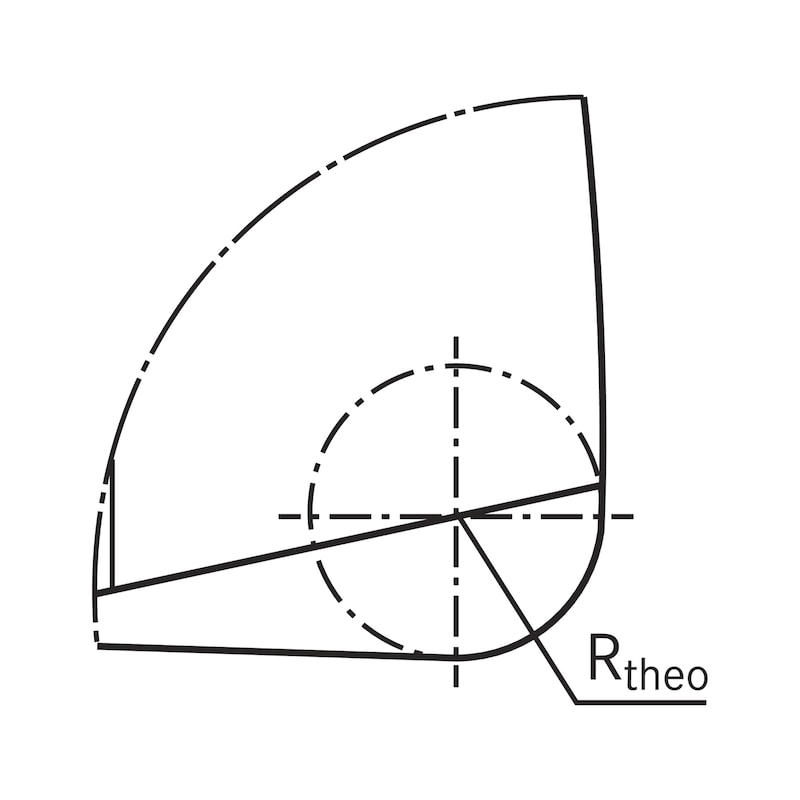

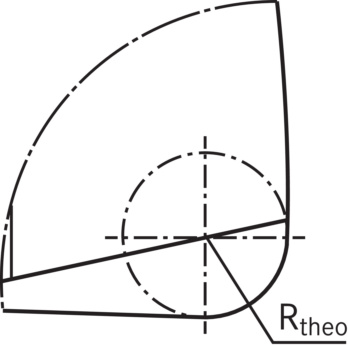

Cutting edge diameter | 5 mm |

Cutting edge length | 10 mm |

Clearance length | 15 mm |

Length | 54 mm |

Clearance diameter | 4.7 mm |

Shank diameter | 6 mm |

fz stainless steel | 0.04 mm |

Product Group | 108 |

Gross Weight | 0.022 kg |