Brand: ATORN

Surface: TiAlN

Length: 150 mm

Art.-no. 11783689

Manufacturer article no. 12160782

EAN 4050293624977

Individual prices for customers after login

Application

for cutting fit tolerances in blind holes on modern CNC machines with steady tool and workpiece clamping, in stainless steels.

Execution

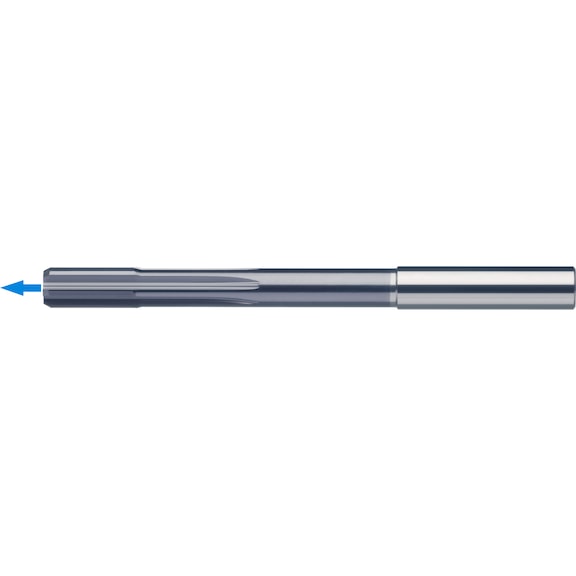

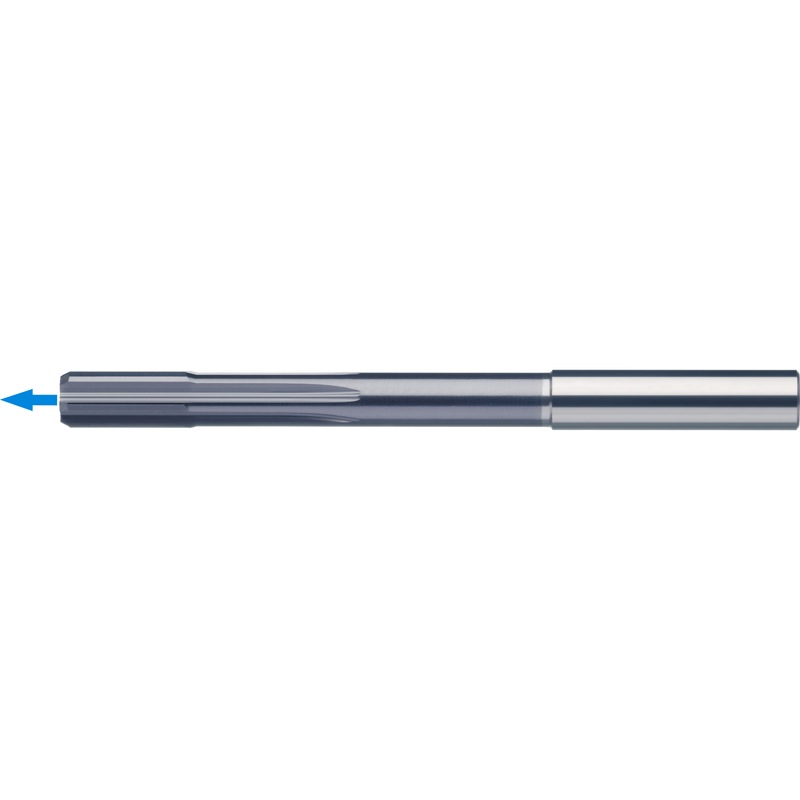

- Straight grooved, extremely variable pitch and internal cooling, type A

Advantage

- Innovative cutting geometry provides very high stability and process reliability, with very high cutting parameters

- High-quality solid carbide cutting material and coating ensure a very long service life

- Internal cooling ensures optimal transportation of chips

Notes

Make sure that tools are accurately and tightly clamped (ideally use a hydro-mechanical clamping chuck or precision collet chuck). Note: Please refer to dimension table.

Brand | ATORN |

EAN | 4050293624977 |

Manufacturer Part Number | 12160782 |

Material to be processed | Stainless steel |

Cutting edge diameter | 18 mm |

Tolerance of fit | H7 |

Type | HPC VA |

Suitable for through hole | No |

Form | A |

Suitable for blind hole | Yes |

Groove type | Straight |

Number of cutting edges | 8 PCS |

Surface | TiAlN |

Cutting material | SC |

Projecting length | 100 mm |

Length | 150 mm |

Shank diameter | 18 mm |

Coolant supply | Internal |

Min./max. diameter (Ø) | 4.0-20.0 mm |

Harmonized System Code | 82076030 |

Product Group | 1BK |

Gross Weight | 0.460 kg |

| Material groups for cutting values | Description regarding DIN | Strength Class [N/mm²] | Material No. | Vc [m/min] | f [mm/U] | Suitability |

|---|---|---|---|---|---|---|

| 1.00 Steels | ||||||

| 1.01 Free machining steel | 9 S 20 | < 900 | 1.0711 | - | - | |

| 1.02 Structural steel | ST 37-2 | <500 | 1.0037 | - | - | |

| 1.03 Structural steel | ST 60-2 | > 500 | 1.7735 | - | - | |

| 1.04 Heat-treated steel | 42 CrMo 4 | <1000 | 1.7225 | - | - | |

| 1.05 Cast iron | GS-45 | <1000 | 1.0446 | - | - | |

| 1.06 Case-hardened steel | 16 MnCr 5 | <1200 | 1.7131 | - | - | |

| 1.07 Ferritic/martensitic stainless steel | X 10 Cr 13 | <1100 | 1.4006 | 20-60 | 0.5-0.6 | ⚫ |

| 1.08 Heat-treated steel | 43 CrMo 4 | >1000 | 1.3563 | - | - | |

| 1.09 Nitriding steel | 31 CrMoV 9 | <1300 | 1.8519 | - | - | |

| 1.10 Tool steel | X 38 CrMoV 5 1 | <1300 | 1.2343 | - | - | |

| 2.00 Stainless steels | ||||||

| 2.01 Austenitic stainless steel | G-X 2 CrNiMo 18 15 | <1100 | 1.3953 | 20-40 | 0.5-0.6 | ⚫ |