Brand: ATORN

Surface: TiAlN

Length: 26 mm

Art.-no. 11785118

Manufacturer article no. 10420196

EAN 4050293618938

Individual prices for customers after login

Application

For HPC reaming of through holes in the diameter range 10.00 mm–40.00 mm

Execution

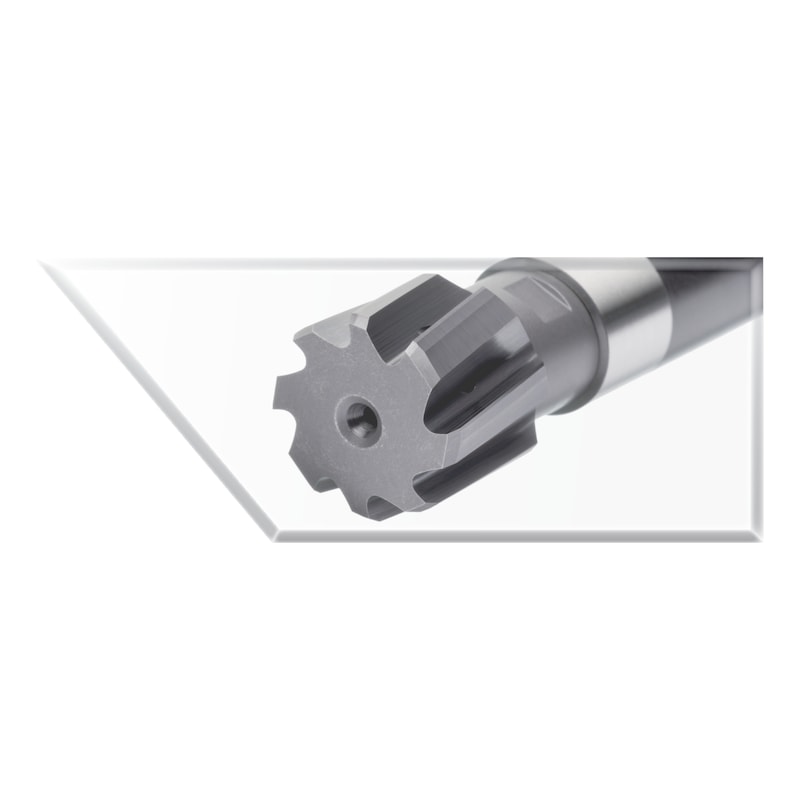

- Left-hand diagonal toothing with extremely uneven pitch

Advantage

- System concentricity in installed state <5 µ

- Internal cooling ensures optimal transportation of chips

- Ground thread and tapered flat face for maximum changeover accuracy and high strength

- Various holder lengths available

- Simple to change in the machine

Notes

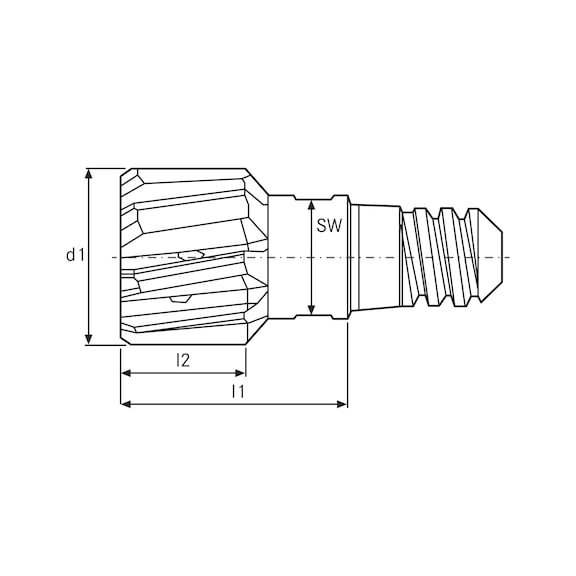

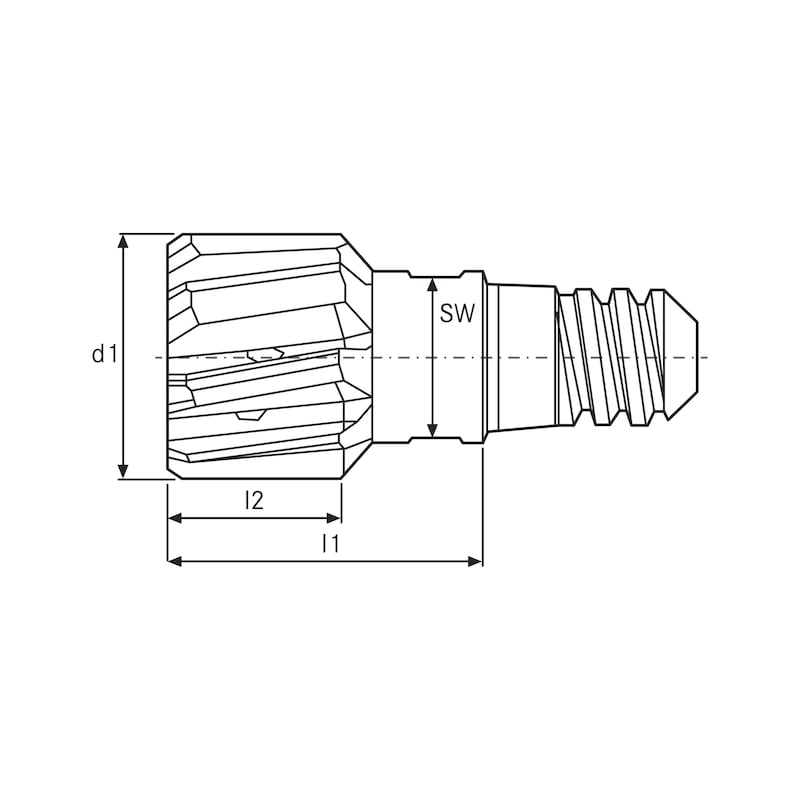

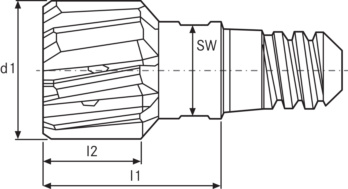

Configurable dimensions available on request. Note: Please refer to dimension table.

| |

Brand | ATORN |

EAN | 4050293618938 |

Manufacturer Part Number | 10420196 |

Material to be processed | Steel, Cast metal |

Surface | TiAlN |

Cutting edge diameter (d1) | 18 mm |

Suitable for through hole | Yes |

Suitable for blind hole | No |

Type | HPC UNI |

Form | B |

Tolerance of fit | H7 |

Replaceable head system | WKS 12 |

Number of teeth (Z) | 8 PCS |

Coolant supply | Internal |

Cutting material | SC |

Tightening torque | 20 Nm |

Cutting direction | Right-hand cutting |

Length (l1) | 26 mm |

Cutting edge length (l2) | 14 mm |

Width across flats (SW) | 13 mm |

Harmonized System Code | 82076030 |

Product Group | 1BK |

Gross Weight | 0.097 kg |

| Material groups for cutting values | Description regarding DIN | Strength Class [N/mm²] | Material No. | Vc [m/min] | f [mm/U] | Suitability |

|---|---|---|---|---|---|---|

| 1.00 Steels | ||||||

| 1.01 Free machining steel | 9 S 20 | < 900 | 1.0711 | 150-160 | 1.0-1.5 | ⚫ |

| 1.02 Structural steel | ST 37-2 | <500 | 1.0037 | 150-160 | 1.0-1.5 | ⚫ |

| 1.03 Structural steel | ST 60-2 | > 500 | 1.7735 | 150-160 | 1.0-1.5 | ⚫ |

| 1.04 Heat-treated steel | 42 CrMo 4 | <1000 | 1.7225 | 150-160 | 1.0-1.5 | ⚫ |

| 1.05 Cast iron | GS-45 | <1000 | 1.0446 | 150-160 | 1.0-1.5 | ⚫ |

| 1.06 Case-hardened steel | 16 MnCr 5 | <1200 | 1.7131 | 150-160 | 1.0-1.5 | ⚫ |

| 1.07 Ferritic/martensitic stainless steel | X 10 Cr 13 | <1100 | 1.4006 | - | - | |

| 1.08 Heat-treated steel | 43 CrMo 4 | >1000 | 1.3563 | 120-160 | 1.0-1.5 | ⚫ |

| 1.09 Nitriding steel | 31 CrMoV 9 | <1300 | 1.8519 | 120-160 | 1.0-1.5 | ⚫ |

| 1.10 Tool steel | X 38 CrMoV 5 1 | <1300 | 1.2343 | 120-160 | 1.0-1.5 | ⚫ |

| 4.00 Cast metal | ||||||

| 4.01 Grey cast iron | GG10 | <260 HB | 0.6010 | 100-120 | 0.8-1.2 | ⚫ |

| 4.02 Spheroidal graphite iron | GGG 40 | <310 HB | 0.7040 | 100-120 | 0.8-1.2 | ⚫ |

| 4.03 Ductile iron | GTW-55 | <280 HB | 0.8055 | 90-110 | 0.7-1.2 | ⚫ |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!