Brand: ATORN

Surface: ULTRA M

Length: 89 mm

DIN: 6537

Art.-no. 11142294

Manufacturer article no. 10481810

EAN 4050293574869

Individual prices for customers after login

Application

For HPC boring in stainless steel, titanium alloys, nickel alloys and special alloys.

Execution

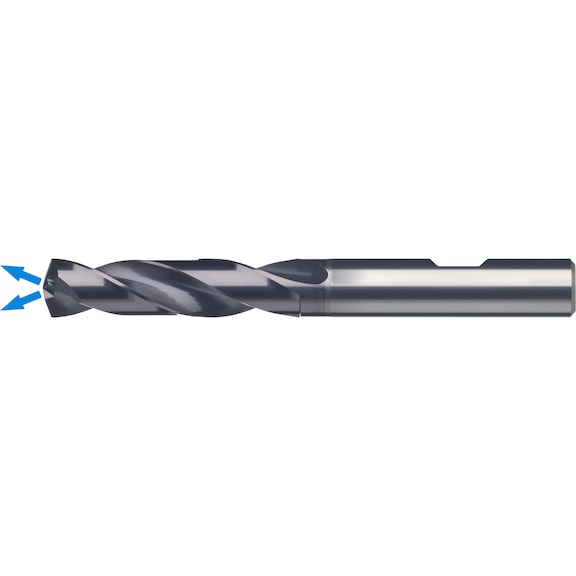

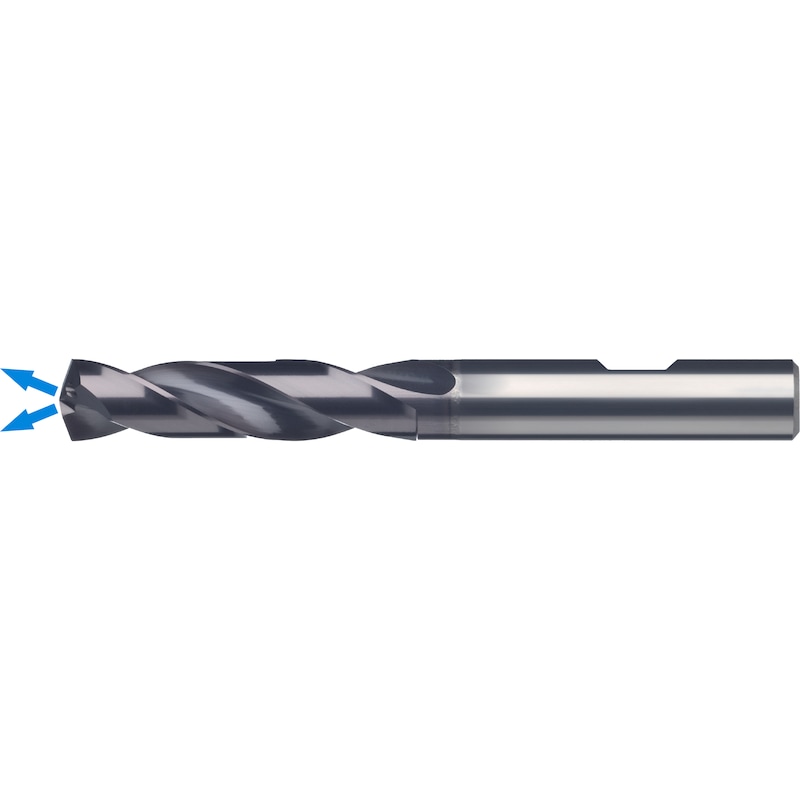

- Solid carbide high-performance drill ULTRA M

- 2 drill heels

- 4 grinding faces

- 30° spiral angle

- Straight main cutting edge

Advantage

- innovative cutting geometry with extremely effective cutting edge

- newly developed form-fitting ULTRA M coating for improved service life

- Cutting edge preparation minimises micro-fractures on the cutter

Brand | ATORN |

EAN | 4050293574869 |

Manufacturer Part Number | 10481810 |

Material to be processed | Stainless steel, Special alloy |

Cutting edge diameter | 9.4 mm |

Tolerance of cutting edge diameter | m7 |

Cutting material | SC |

Surface | ULTRA M |

Max. drilling depth (D) | 3xD |

Type | HPC VA |

Coolant supply | Internal |

Tool holding device | HB parallel shank |

Angle of the tip | 140 Degree |

Shank diameter | 10 mm |

Chip flute length | 47 mm |

Length | 89 mm |

f stainless steel | 0.14 mm/r |

DIN | 6537 |

Harmonized System Code | 82075050 |

Product Group | 113 |

Gross Weight | 0.070 kg |

| Material groups for cutting values | Description regarding DIN | Strength Class [N/mm²] | Material No. | Vc [m/min] | f [mm/r] with diameter | Suitability |

|---|---|---|---|---|---|---|

| 1.00 Steels | ||||||

| 1.01 Free machining steel | 9 S 20 | < 900 | 1.0711 | - | - | |

| 1.02 Structural steel | ST 37-2 | <500 | 1.0037 | - | - | |

| 1.03 Structural steel | ST 60-2 | > 500 | 1.7735 | - | - | |

| 1.04 Heat-treated steel | 42 CrMo 4 | <1000 | 1.7225 | - | - | |

| 1.05 Cast iron | GS-45 | <1000 | 1.0446 | - | - | |

| 1.06 Case-hardened steel | 16 MnCr 5 | <1200 | 1.7131 | - | - | |

| 1.07 Ferritic/martensitic stainless steel | X 10 Cr 13 | <1100 | 1.4006 | 70-80 | 0.16-0.2 | ⚫ |

| 1.08 Heat-treated steel | 43 CrMo 4 | >1000 | 1.3563 | - | - | |

| 1.09 Nitriding steel | 31 CrMoV 9 | <1300 | 1.8519 | - | - | |

| 1.10 Tool steel | X 38 CrMoV 5 1 | <1300 | 1.2343 | - | - | |

| 2.00 Stainless steels | ||||||

| 2.01 Austenitic stainless steel | G-X 2 CrNiMo 18 15 | <1100 | 1.3953 | 50-60 | 0.08-0.1 | ⚫ |

| 5.00 Special alloys | ||||||

| 5.01 Titanium alloy | TiAI5Sn2,5 | <1200 | 3.7115 | 25-35 | 0.08-0.1 | ⚫ |

| 5.02 Nickel-based alloy | NiCr21Mo | <1400 | 2.4858 | 25-35 | 0.08-0.1 | ⚫ |

| 5.03 Super alloys | X45CrSi 9 3 | <1400 | 1.4718 | 25-30 | 0.08-0.1 | ⚫ |