Brand: ATORN

Surface: TiAlN

Length: 102 mm

Art.-no. 11134100

Manufacturer article no. 12040014

EAN 4050293357011

Individual prices for customers after login

Application

Countersink and thread core holes are manufactured in one machining step. Sturdy short design in particular for using in NC machines and automatic machines.

Execution

- Heavy-duty stepped drill bit with universal precision grinding

Advantage

- precise alignment of drill diameter and countersink diameter, lower process costs

- universal use, therefore tool costs are reduced to a minimum and user flexibility is increased

| |

Brand | ATORN |

EAN | 4050293357011 |

Manufacturer Part Number | 12040014 |

Material to be processed | Universal use |

Cutting material | SC |

Surface | TiAlN |

Type | N |

Angle of the tip | 140 Degree |

Tool holding device | HA parallel shank |

Suitable for screw thread | M10 |

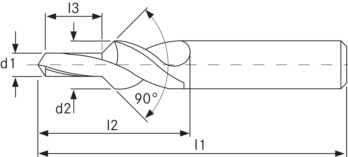

Pilot hole diameter (d1) | 8.5 mm |

Spot-facer diameter (d2) | 12 mm |

Pilot hole length (l3) | 25.5 mm |

Chip flute length (l2) | 55 mm |

Length (l1) | 102 mm |

Shank diameter | 12 mm |

f steel 1300 | 0.15 mm/r |

Harmonized System Code | 82075070 |

Product Group | 113 |

Gross Weight | 0.124 kg |

| Material groups for cutting values | Description regarding DIN | Strength Class [N/mm²] | Material No. | Vc [m/min] | f [mm/r] with diameter | Suitability |

|---|---|---|---|---|---|---|

| 1.00 Steels | ||||||

| 1.01 Free machining steel | 9 S 20 | < 900 | 1.0711 | 60-90 | 0.2-0.25 | ⚫ |

| 1.02 Structural steel | ST 37-2 | <500 | 1.0037 | 60-90 | 0.2-0.25 | ⚫ |

| 1.03 Structural steel | ST 60-2 | > 500 | 1.7735 | 60-85 | 0.2-0.25 | ⚫ |

| 1.04 Heat-treated steel | 42 CrMo 4 | <1000 | 1.7225 | 50-70 | 0.2-0.25 | ⚫ |

| 1.05 Cast iron | GS-45 | <1000 | 1.0446 | 40-70 | 0.15-0.17 | ⚫ |

| 1.06 Case-hardened steel | 16 MnCr 5 | <1200 | 1.7131 | 40-70 | 0.15-0.17 | ⚫ |

| 1.07 Ferritic/martensitic stainless steel | X 10 Cr 13 | <1100 | 1.4006 | 20-30 | 0.15-0.17 | ⚫ |

| 1.08 Heat-treated steel | 43 CrMo 4 | >1000 | 1.3563 | 30-60 | 0.15-0.17 | ⚫ |

| 1.09 Nitriding steel | 31 CrMoV 9 | <1300 | 1.8519 | 30-50 | 0.15-0.17 | ⚫ |

| 1.10 Tool steel | X 38 CrMoV 5 1 | <1300 | 1.2343 | 20-40 | 0.15-0.17 | ⚫ |

| 2.00 Stainless steels | ||||||

| 2.01 Austenitic stainless steel | G-X 2 CrNiMo 18 15 | <1100 | 1.3953 | 20-30 | 0.15-0.17 | ⚪ |

| 3.00 Non-ferrous metals | ||||||

| 3.01 Long-chipping aluminium | AI99.9 | <500 | 3.0305 | 150-250 | 0.22-0.27 | ⚫ |

| 3.02 Short-chipping aluminium | G-AISi12 | <500 | 3.2581 | 150-180 | 0.22-0.27 | ⚫ |

| 3.03 Copper alloy bronze, long-chipping | CuSn4 | <1200 | 2.1016 | 80-120 | 0.2-0.25 | ⚪ |

| 3.04 Copper alloy bronze, short-chipping | CuNi12Zn24 | <850 | 2.0730 | 80-120 | 0.2-0.25 | ⚫ |

| 3.05 Copper alloy brass, long-chipping | Cu Zn 20 | <600 | 2.0250 | 120-180 | 0.22-0.27 | ⚫ |

| 3.07 Thermoplastic | Cu Zn 39 Pb 3 | <600 | 2.0381 | 100-150 | 0.22-0.27 | ⚫ |

| 3.07 Thermoplastic | PVC, Acrylglas | <100 | 70-120 | 0.2-0.25 | ||

| 3.08 Duroplast | Bakelit, Melamin | <150 | 50-70 | 0.2-0.25 | ||

| 3.09 Fibre-reinforced plastics | CFK, GFK | <1500 | 30-60 | 0.2-0.25 | ||

| 3.10 Graphite | C8000 | <60 | 30-50 | 0.2-0.25 | ||

| 3.11 Composite materials | - | - | ||||

| 4.00 Cast metal | ||||||

| 4.01 Grey cast iron | GG10 | <260 HB | 0.6010 | 80-110 | 0.2-0.25 | ⚫ |

| 4.02 Spheroidal graphite iron | GGG 40 | <310 HB | 0.7040 | 80-110 | 0.2-0.25 | ⚫ |

| 4.03 Ductile iron | GTW-55 | <280 HB | 0.8055 | 80-110 | 0.2-0.25 | ⚫ |

| 5.00 Special alloys | ||||||

| 5.01 Titanium alloy | TiAI5Sn2,5 | <1200 | 3.7115 | 20-30 | 0.2-0.25 | ⚪ |

| 5.02 Nickel-based alloy | NiCr21Mo | <1400 | 2.4858 | 20-30 | 0.2-0.25 | |

| 5.03 Super alloys | X45CrSi 9 3 | <1400 | 1.4718 | 20-30 | 0.2-0.25 | |