Brand: ATORN

Surface: TiAlN

Length: 90 mm

Art.-no. 13498448

Manufacturer article no. 11190374

EAN 4050293272079

Individual prices for customers after login

Application

For manufacturing right-handed and left-handed NPT threads (National Piper Tap) in through and blind holes on CNC and conventional machines in the steel, stainless steel, NF metal, cast and special alloy material groups up to a strength of 1500 N/mm² in single part and series production.

Execution

- With collar recess.

Advantage

- Innovative cutting geometry for very high dimensional accuracy, process reliability and chip removal.

- Deep thread depth achievable due to collar recess between thread part and shank.

Brand | ATORN |

Tool holding device | HA parallel shank |

Main EAN Code | 4050293272079 |

Manufacturer Part Number | 11190374 |

Cutting material | SC |

Surface | TiAlN |

Hole type | Clearance/blind hole ≤ 2xD |

Coolant supply | Internal |

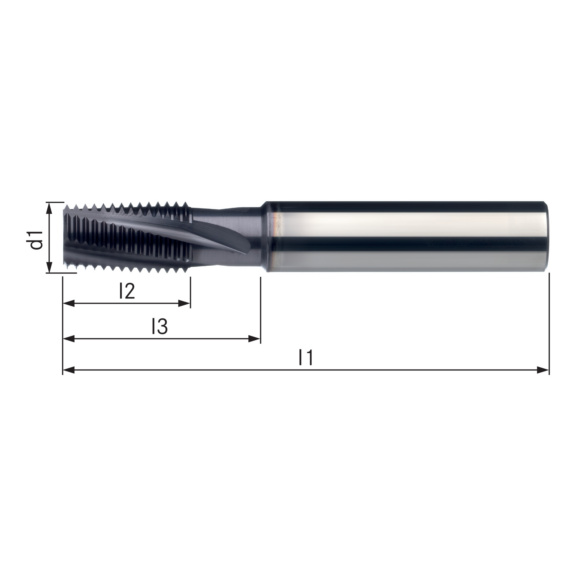

Cutting edge diameter (d1) | 18.5 mm |

Suitable from thread size | NPT 1 inch |

Length (l1) | 90 mm |

Cutting edge length (l2) | 23.19 mm |

Effective length of thread milling (l3) | 23.19 mm |

Shank diameter | 20 mm |

Number of cutting edges | 5 PCS |

f steel 1000 | 0.08 mm/r |

Gross Weight | 0.336 kg |

| Material groups for cutting values | Description regarding DIN | Strength Class [N/mm²] | Material No. | Vc [m/min] | f [mm/r] with diameter | Suitability |

|---|---|---|---|---|---|---|

| 1.00 Steels | ||||||

| 1.01 Free machining steel | 9 S 20 | < 900 | 1.0711 | 100-250 | ⚫ | |

| 1.02 Structural steel | ST 37-2 | <500 | 1.0037 | 100-250 | ⚫ | |

| 1.03 Structural steel | ST 60-2 | > 500 | 1.7735 | 100-220 | ⚫ | |

| 1.04 Heat-treated steel | 42 CrMo 4 | <1000 | 1.7225 | 110-180 | ⚫ | |

| 1.05 Cast iron | GS-45 | <1000 | 1.0446 | 110-180 | ⚫ | |

| 1.06 Case-hardened steel | 16 MnCr 5 | <1200 | 1.7131 | 90-160 | ⚫ | |

| 1.07 Ferritic/martensitic stainless steel | X 10 Cr 13 | <1100 | 1.4006 | 110-170 | ⚫ | |

| 1.08 Heat-treated steel | 43 CrMo 4 | >1000 | 1.3563 | 60-140 | ⚫ | |

| 1.09 Nitriding steel | 31 CrMoV 9 | <1300 | 1.8519 | 60-120 | ⚫ | |

| 1.10 Tool steel | X 38 CrMoV 5 1 | <1300 | 1.2343 | 60-100 | ⚫ | |

| 2.00 Stainless steels | ||||||

| 2.01 Austenitic stainless steel | G-X 2 CrNiMo 18 15 | <1100 | 1.3953 | 110-150 | ⚫ | |

| 3.00 Non-ferrous metals | ||||||

| 3.01 Long-chipping aluminium | AI99.9 | <500 | 3.0305 | 160-300 | ⚫ | |

| 3.02 Short-chipping aluminium | G-AISi12 | <500 | 3.2581 | 150-280 | ⚫ | |

| 3.03 Copper alloy bronze, long-chipping | CuSn4 | <1200 | 2.1016 | 100-250 | ⚫ | |

| 3.04 Copper alloy bronze, short-chipping | CuNi12Zn24 | <850 | 2.0730 | 100-250 | ⚫ | |

| 3.05 Copper alloy brass, long-chipping | Cu Zn 20 | <600 | 2.0250 | 160-280 | ⚫ | |

| 3.07 Thermoplastic | PVC, Acrylglas | <100 | 100-400 | ⚫ | ||

| 3.07 Thermoplastic | Cu Zn 39 Pb 3 | <600 | 2.0381 | 160-280 | ⚫ | |

| 3.08 Duroplast | Bakelit, Melamin | <150 | 100-300 | ⚫ | ||

| 3.09 Fibre-reinforced plastics | CFK, GFK | <1500 | - | ⚫ | ||

| 3.10 Graphite | C8000 | <60 | - | ⚫ | ||

| 3.11 Composite materials | - | ⚫ | ||||

| 4.00 Cast metal | ||||||

| 4.01 Grey cast iron | GG10 | <260 HB | 0.6010 | 70-150 | ⚫ | |

| 4.02 Spheroidal graphite iron | GGG 40 | <310 HB | 0.7040 | 70-130 | ⚫ | |

| 4.03 Ductile iron | GTW-55 | <280 HB | 0.8055 | 70-130 | ⚫ | |

| 5.00 Special alloys | ||||||

| 5.01 Titanium alloy | TiAI5Sn2,5 | <1200 | 3.7115 | 20-80 | ⚫ | |

| 5.02 Nickel-based alloy | NiCr21Mo | <1400 | 2.4858 | 20-80 | ⚫ | |

| 5.03 Super alloys | X45CrSi 9 3 | <1400 | 1.4718 | 20-80 | ⚫ | |