For detailed information, other images and documents, please select individual articles from the following table.

Products

Application

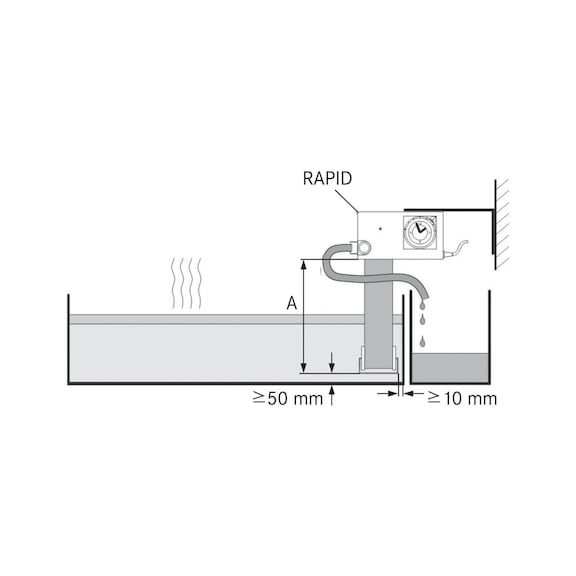

RAPID is used for the fully automatic, time-controlled and continuous maintenance of water-miscible cooling lubricants and process baths. During the maintenance phase of your cooling lubricant, RAPID removes unwanted floating tramp oils, lime soaps and suspended solids. These impurities and a lack of oxygen balance can cause cooling lubricants to become effective breeding grounds for bacteria, viruses, yeasts and fungi. These influences can cause skin irritation, foaming and odour formation. Tramp oils, lime soaps and suspended solids also significantly impair production quality. Thanks to the patented skimmer process, these contaminants stick to the belt due to a high adhesive force. The contaminants are then discharged via the belt. This allows you to get the best performance out of your machine and tools.

Execution

- Compact stainless steel housing with double scraper

- ¾ oil drain hose, bi-directional

- With integrated timer

- various operating options (interval/continuous operation)

- Device delivered without belt

Advantage

- Prolongs service life of lubricants and tools

- Consistently clean and biostable coolant

- Lower personnel absences due to skin conditions

- Reduces operating and disposal costs

- prevents unpleasant odours, easy to handle

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!