Brand: ATORN

Length: 101 mm

Art.-no. 13498680

Manufacturer article no. 11940432

EAN 4050293208214

Individual prices for customers after login

Application

For producing metric right-hand and left-hand threads on CNC machines, in steel, stainless steel, non-ferrous metals, cast iron and special alloy material groups up to a strength of 1500 N/mm².

Execution

- Single-edge cutter in sub-profile design

Advantage

- Innovative cutting geometry for very high dimensional accuracy, process reliability and chip removal.

- High-quality cutting material and cutting edge finish for very high service life requirements

- Low tool costs thanks to high variability in the thread diameter, just one tool required for right-hand thread and left-hand thread

| |

Brand | ATORN |

Main EAN Code | 4050293208214 |

Manufacturer Part Number | 11940432 |

Min./max. pitch internal | 2.0-3.0 mm |

Min./max. pitch external | 1.75-2.5 mm |

Min./max. number of thread starts per inch internal | 13-8 |

Min./max. number of thread starts per inch external | 15-10 |

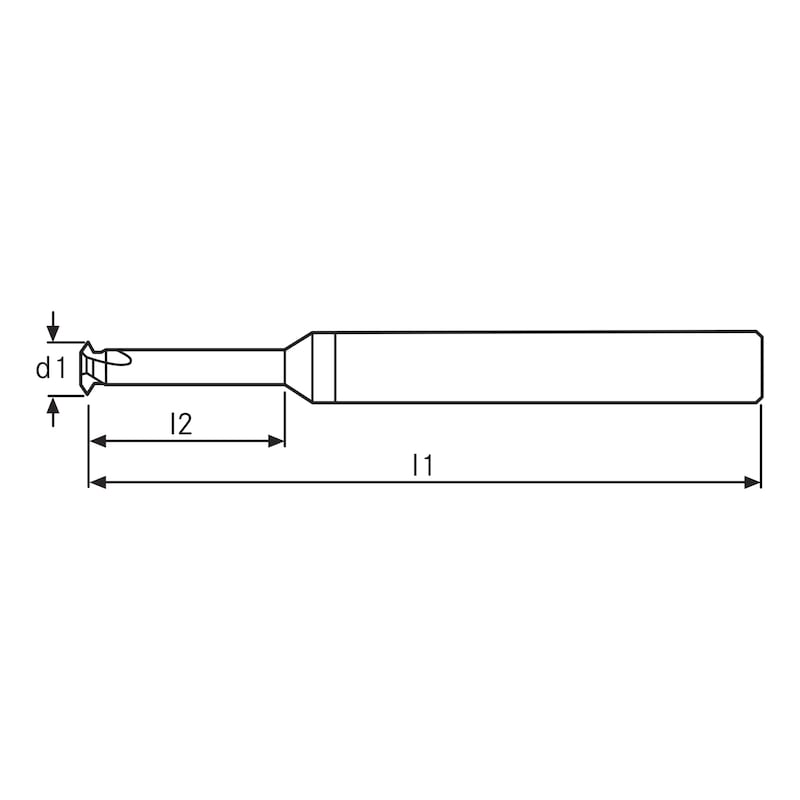

Cutting edge diameter | 14 mm |

Shank diameter | 16 mm |

Effective length of thread milling (l2) | 45 mm |

Length (l1) | 101 mm |

Coolant supply | Internal |

Number of grooves | 5 PCS |

Machining type | Inside, Outside |

Number of cutting edges | 1 PCS |

Product Group | 132 |

Gross Weight | 0.293 kg |