Document the accuracy of your work with a calibration certificate.

We work together with our independent accredited partner, Trescal GmbH, to offer a calibration service. If can be used both when purchasing new measuring and test devices and for the periodic recalibration of all of your measuring and test equipment.

Manufacturer-independent calibration and measuring technology services are documented using a works or DAkkS calibration certificate (as specified by the customer) so that you are always "audit-ready".

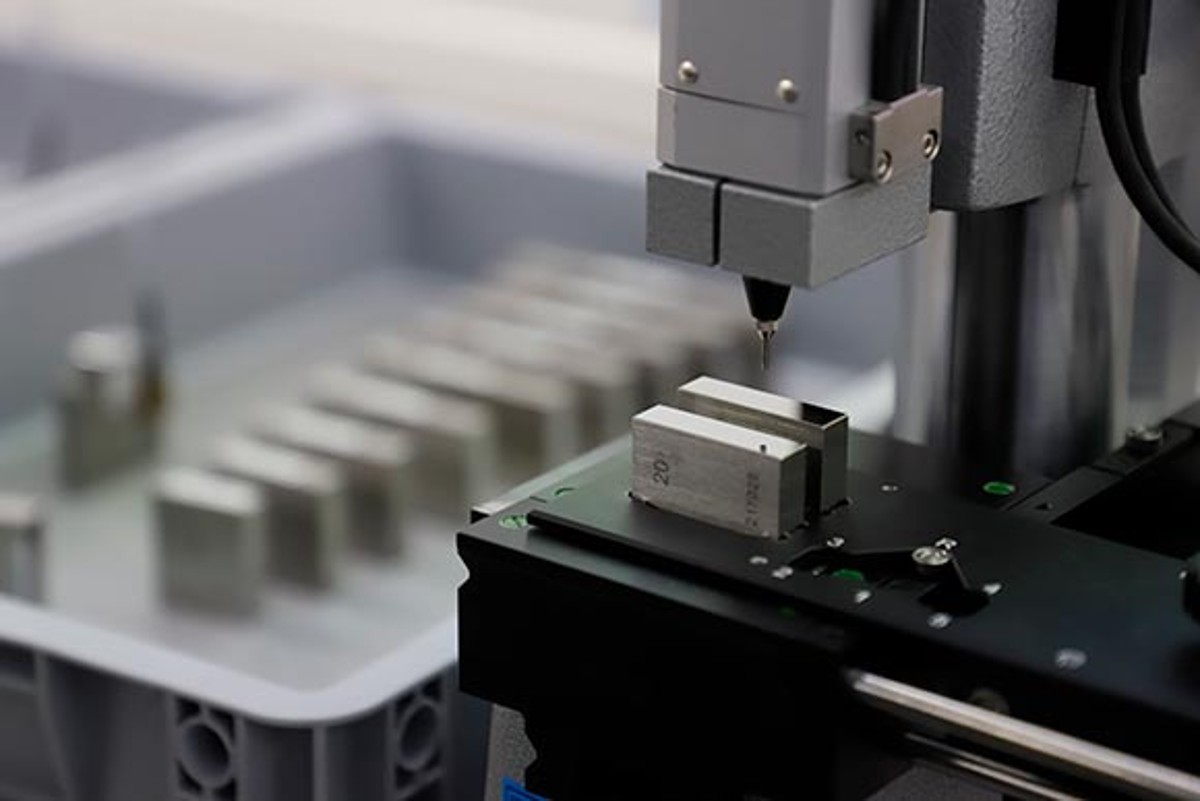

Calibration and Recalibration at HAHN+KOLB

Demonstrate the precise operational capability of your new measuring instrument and ensure your product and service quality through regular calibration – with us as your partner.

Simply order the measuring instrument you need from us and specify that it should be calibrated. We will deliver the measuring instrument to you, including a printed calibration certificate. Of course, we will provide you with the calibration data via a standardized interface according to VDI 2623, if desired.

Why is calibration and recalibration necessary?

There are numerous reasons for calibration, whether it is to check the performance and accuracy of devices, ensure product quality, or comply with internal and external regulations.

The traceability of measuring instruments is strictly mandatory according to standard requirements. For this purpose, measuring instruments are usually calibrated by an accredited laboratory. A DAkkS calibration is strictly required in accordance with IATF 16949 or specific customer requirements. Factory calibration is sufficient to meet the requirements of DIN EN ISO 9001, provided there are no additional customer requirements.

How often should calibration be performed?

The calibration interval depends on various factors; there is no one-size-fits-all answer.

The following variables affect the frequency of calibration:

- The accuracy requirements

- The workload of the measuring instrument

- The operating conditions of the measuring instrument

- The stability history of the measuring instrument

- The manufacturer's recommendation for the measuring instrument

What types of calibration are available?

The type of calibration to be performed depends on your application and requirements. Do you need an IATF 16949 certification or a DAkkS calibration? If you only need to comply with DIN EN ISO 9001, then ISO/factory calibration is sufficient.

There is a distinction between DAkkS calibration and factory calibration. The higher-quality DAkkS calibration meets the requirements of IATF 16949 as well as specific customer requirements. To meet the standards of DIN EN ISO 9001, factory calibration is sufficient.

The two types of calibration differ in terms of national and international recognition. DAkkS calibration certificates are internationally recognized and legally valid. This is indicated by the accreditation symbol on the calibration certificate. The calibration procedures used are regularly reviewed by the accreditation body to demonstrate conformity with DIN EN ISO/IEC 17025.

ISO/factory calibration is carried out in accordance with the guidelines VDI/VDE/DGQ 2618 and following. The laboratory is responsible for the correct compliance with the guidelines and the issuance of the factory calibration certificate.

Your benefits:

- Compliance with the quality system requirements

- Safety for employees and customers

- Maintenance of product quality

- Reduction of costs

- Conservation of resources